Supply chain management and integration has important

functions for businesses that desire to create higher levels of financial performance.

Since all companies work with related companies in either formal or informal

linkages, such as suppliers and distributors, it is important to ensure

information is transferred effectively between entities to enhance operations

on both sides. Research by Kannan & Keah (2010) show how companies that

integrate their supply chains to a wider extent develop a number of advantages.

Supply chain management entails businesses

associated with the development, building, distributing, and returning of products/services.

It has been defined as the “cross

functional integration within the firm and across the network of firms that

comprise the supply chain”

(Lambert, 2004). The management of supply chain has come to mean better

integration with the supply chain elements to produce value.

Integration is the creation of inter-firm linkages.

Sharing information, building stronger ways to coordinate resources and

collaborating on mutual goals creates efficiencies. These efficiencies may lead

to cheaper processes, faster movement of products, or better attainment of

resources. The functioning of the supply chain has a direct effect on the

success of the organization.

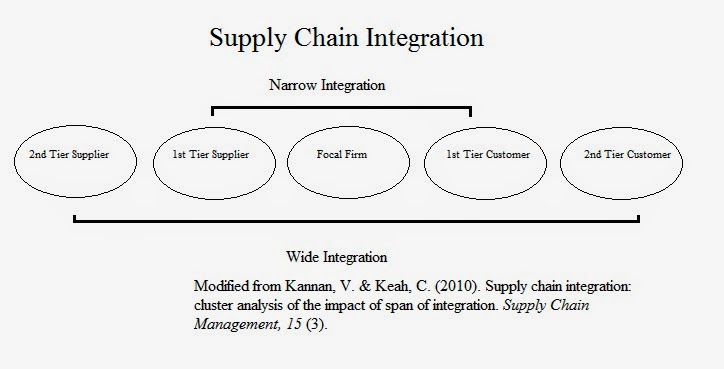

There are reasons why some firms seek narrow

integration versus wider integration. The factors leading to higher levels of

performance can be difficult to understand and master. Significant research,

resources and time are invested into the supply chain to create higher levels

of efficiencies. Being too wide in orientation can lead to lack of focus and

goal confusion.

The researchers found that by moving beyond first

tear suppliers offered significant savings and performance improvements that

result in faster product development times, higher sales and strengthened

quality. The second tier suppliers have a significant impact on how the whole

system functions as an entity. Those companies that fail to consider

information from second tier suppliers have a lack of context in which to

understand supply chain information putting them at a disadvantage.

Kannan, V. & Keah, C. (2010). Supply chain

integration: cluster analysis of the impact of span of integration. Supply Chain Management, 15 (3).

Lambert, D. (2004), Supply Chain Management: Processes, Partnerships,

Performance. Supply Chain Management Institute, Sarasota, FL.